Project Description

SABS 664 gate valve resilient seat, which can be used in water supply and drainage project.

SABS 664 gate valve resilient seat technical specification:

Valve Design: SABS 664

Face to Face: SABS 664

Flange Drilling: EN 1092-2/ ISO 7005-2

Hydraulic Test: EN 12266/ ISO 5208

Shell Test Pressure: 24 bar

Sealing Test Pressure: 17.6 bar

The main advantages of gate valve include:

1. The fluid resistance of the valve is small. Because the valve body of gate valve is straight-through type and the flow of the medium doesn’t change direction, the fluid resistance of it is small compared with other kinds of valves.

2. The sealing performance is better than that of other shut-off valve. The opening and closing of it is more conveniently.

3. The range of applications is more wider. In addition to steam, oil and other media, it can be used in medium containing granular solid and with a large viscosity. It can also be used as air-venting valve and low vacuum system valve.

4. Gate valve has dual flow directions. It’s not subject to the flow directions of the medium. Therefore, it is suitable for use in pipeline where the medium may change the flow direction. It is also easy to install.

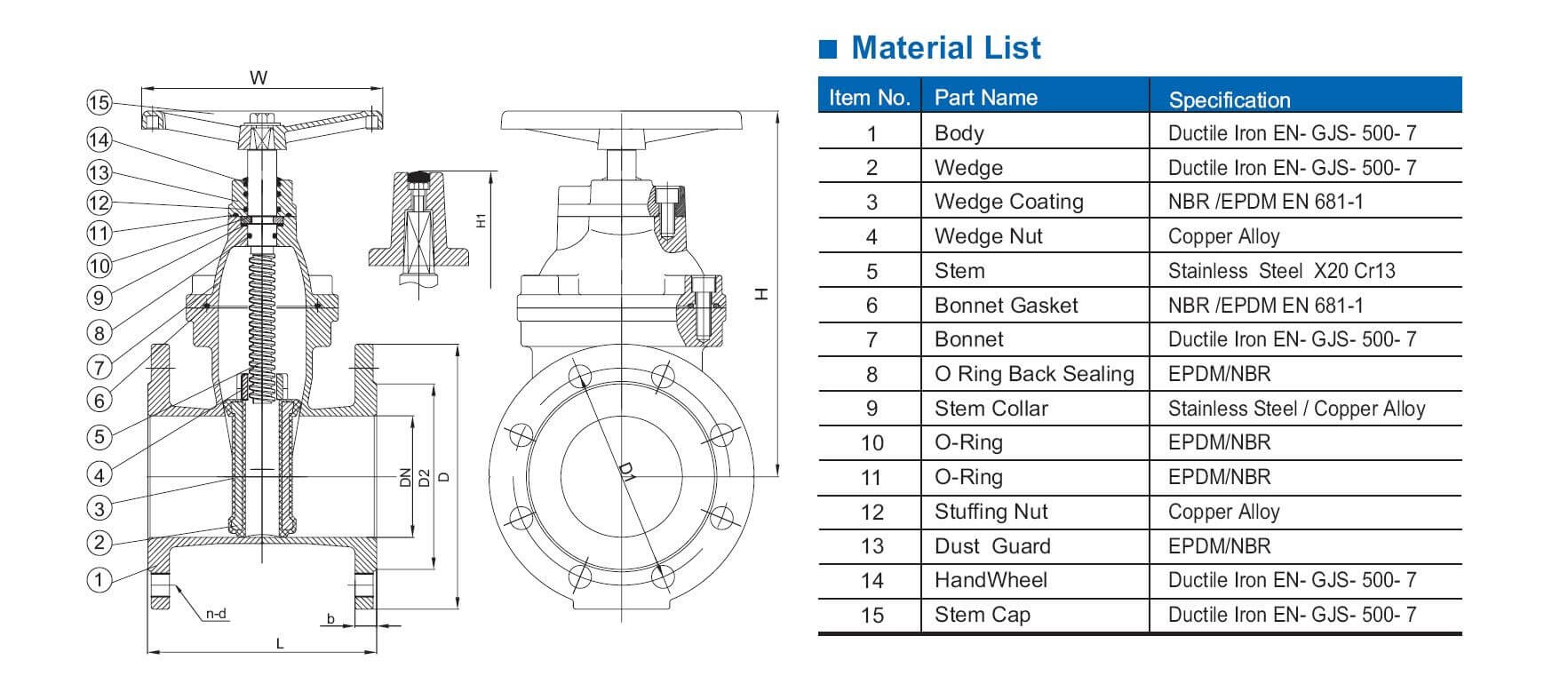

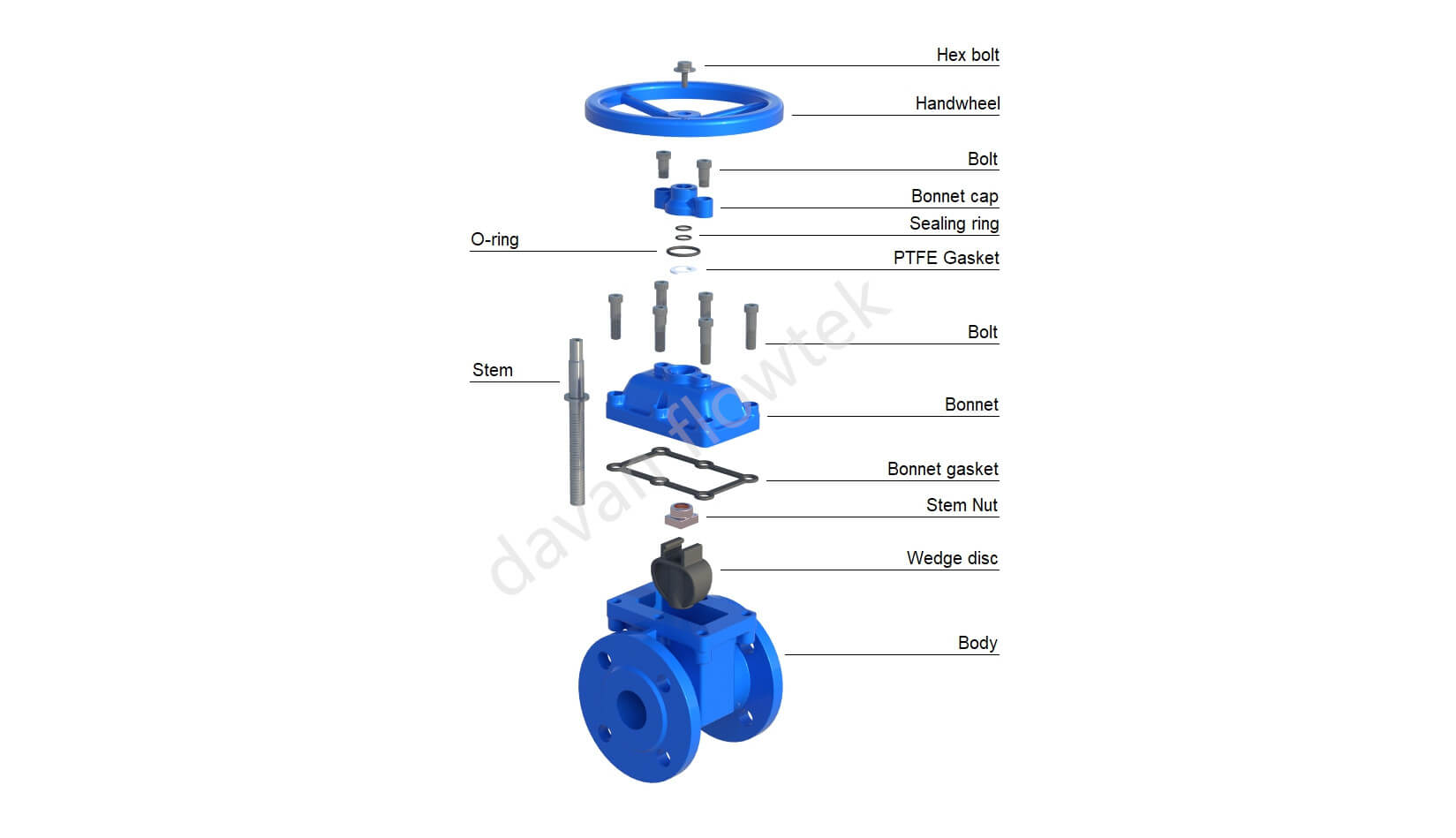

SABS 664 gate valve resilient seat material list

Item No. | Part Name | Specification |

1 | Body | Ductile Iron EN-GJS-500-7 |

2 | Wedge | Ductile Iron EN-GJS-500-7 |

3 | Wedge Coating | NBR/ EPDM EN681-1 |

4 | Wedge Nut | Copper Alloy |

5 | Stem | Stainless Steel X20 Cr13 |

6 | Bonnet Gasket | NBR/ EPDM EN681-1 |

7 | Bonnet | Ductile Iron EN-GJS-500-7 |

8 | O Ring Back Sealing | EPDM/ NBR |

9 | Stem Collar | Stainless Steel/ Copper Alloy |

10 | O-Ring | EPDM/ NBR |

11 | O-Ring | EPDM/ NBR |

12 | Gland Flange | Copper Alloy |

13 | Dust Guard | EPDM/ NBR |

14 | Hand wheel | Ductile Iron EN-GJS-500-7 |

15 | Stem Cap | Ductile Iron EN-GJS-500-7 |