Butterfly valve refers to the valve that the opening and closing parts (butterfly disc) are driven by the stem and rotate around the axis of the stem.

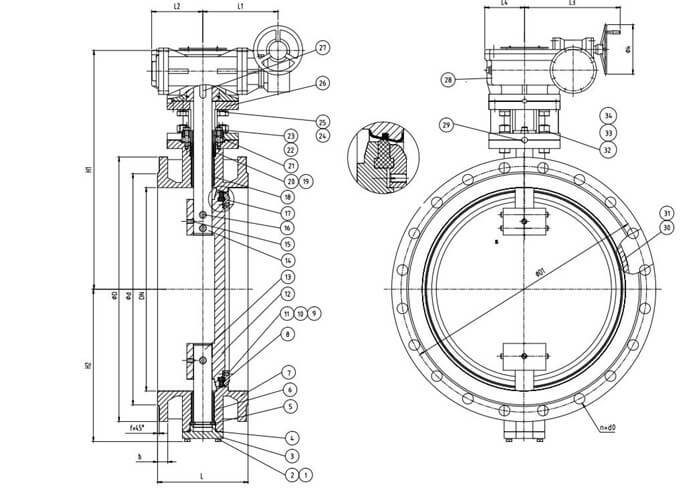

The butterfly valve consists of valve body, stem, disc and a sealing ring. The valve body is cylindrical, with a short structure length and a built-in disc-shaped.

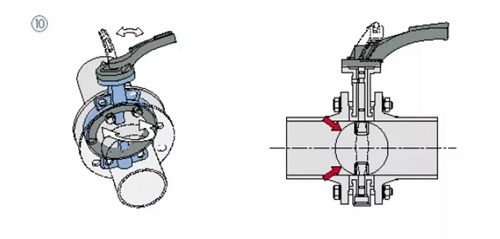

The valve is driven by the valve stem and can rotate from 0 to 90 degrees. When it is 0 degrees, the butterfly plate is vertically closed with the axis of the valve body, and the butterfly plate is rotated 90 degrees.

When the axis of the butterfly plate is consistent with the axis of the valve body, it is all opened. By changing the deflection angle of the disc, the flow of the media can be controlled.

Butterfly valve is a kind of regulating valve with simple structure, and it can also be used for switch control of low pressure pipeline.

The butterfly valve pipeline is mainly used for cutting off and throttling. Its main advantages are short length and light weight.

Compared with the gate valve, the butterfly valve has the advantages of short opening and closing time, small operating torque, small installation space and light weight, and the opening and closing of the butterfly valve is easy to be combined with various driving devices, and has good durability and reliability.

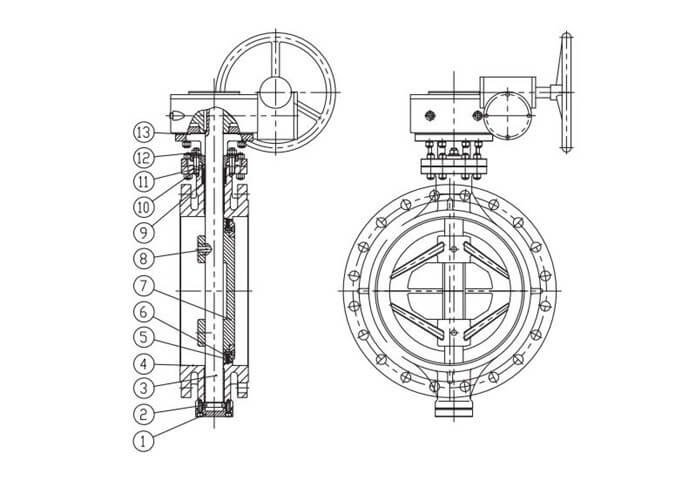

The butterfly valve and the butterfly stem have no self-locking ability, so for the positioning of the butterfly plate, a worm gear reducer should be installed on the valve stem.

The use of worm gear reducer can not only make the butterfly plate have self-locking ability, make the butterfly plate stop in any position, but also improve the operation performance of the valve.

The industrial special butterfly valve is characterized by high temperature resistance, high pressure range, large nominal size of the valve, the valve body is made of carbon steel, and the sealing ring of the valve plate is made of metal ring instead of rubber ring.

The large high temperature butterfly valve is made of steel plate welding, which is mainly used for flue duct and gas pipeline of high temperature medium.

Generally speaking, the butterfly valve has the advantages of simple structure, small volume, light weight and easy adjustment; convenient opening and closing, labor-saving, low fluid resistance and convenient operation; it can transport mud and accumulate the least liquid at the mouth of the pipe; good sealing can be achieved under low pressure.

The disadvantage of butterfly valve is: small range of operating pressure and working temperature, poor tightness.

The butterfly valve is driven by manual, worm gear, electric actuator, pneumatic actuator and other ways, which can realize remote control and automatic operation.

The driving mode of butterfly valve can be manual, electric or pneumatic, and turbine worm is often used in manual mode.

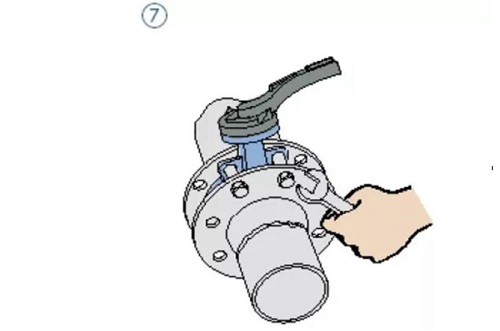

Structure of butterfly valve

The center line butterfly valve is also called the center-line seal butterfly valve or the center seal butterfly valve. The rotary center (that is, the center of the valve stem) of the butterfly plate and the middle line butterfly plate on the valve seat is located on the center line of the valve body , and the sealing surface section of the butterfly plate, and the valve seat is made of EPDM/NBR or other rubber.

When the butterfly plate is closed, the outer circle of the butterfly plate squeezes the synthetic rubber valve seat, which causes the elastic change of the valve seat and forms the elastic force as the sealing specific pressure to ensure the sealing of the butterfly valve.

This kind of valve can be designed as flanged connection and single clamp connection.

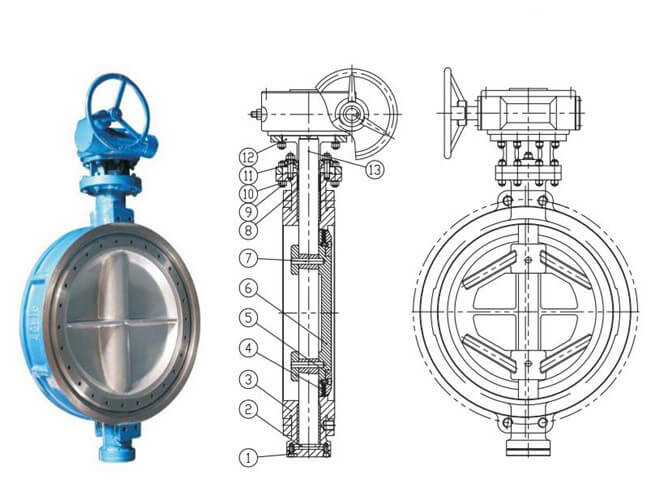

The double eccentric seal butterfly valve is further improved on the basis of the single eccentric butterfly valve.

Its structure is characterized by that the shaft axis of the valve stem deviates from the center of the butterfly plate and the center of the valve shaft of the body valve.

The double eccentric seal butterfly valve plate rotary center (that is, the valve shaft center) forms a dimension offset with the valve plate sealing section, and forms a dimension valve plate centerline offset with the valve body centerline.

Because on the basis of the single eccentric seal butterfly valve, the rotary center of the Amura valve plate (that is, the valve shaft center) and the valve body double eccentric seal butterfly valve seal centerline form a dimension offset, when the double eccentric seal butterfly valve is in a fully open state, the valve plate sealing surface will be completely separated from the valve seat sealing surface.

And a larger gap is formed between the valve plate sealing surface and the seat sealing surface than in the single eccentric seal butterfly valve.

Due to the appearance of dimension b offset, the rotation radius of the valve plate will be divided into long radius rotation and short radius rotation.

On the large half circle of the valve plate with long radius rotation, the tangent of the rotation track of the sealing surface of the valve plate will form an angle with the sealing surface of the valve seat. When the valve plate is opened and closed, the sealing surface of the valve plate is gradually separated from and extruded from the sealing surface of the valve seat.

As a result, the mechanical wear and abrasion between the two tight covers of the butterfly valve seal pair during the opening and closing of the valve plate can be further reduced.

When this kind of butterfly valve is opened, the butterfly plate is quickly separated from the valve seat, thus greatly reducing the unnecessary excessive extrusion and scratching between the butterfly plate and the valve seat.

For example, the opening resistance is reduced, the wear is reduced, and the life of the valve seat is improved.

Double eccentric butterfly valve can use metal seat and can be used in high temperature field.

And it is mainly suitable for river closure and regulation on waterway lines.

[/fusion_text]

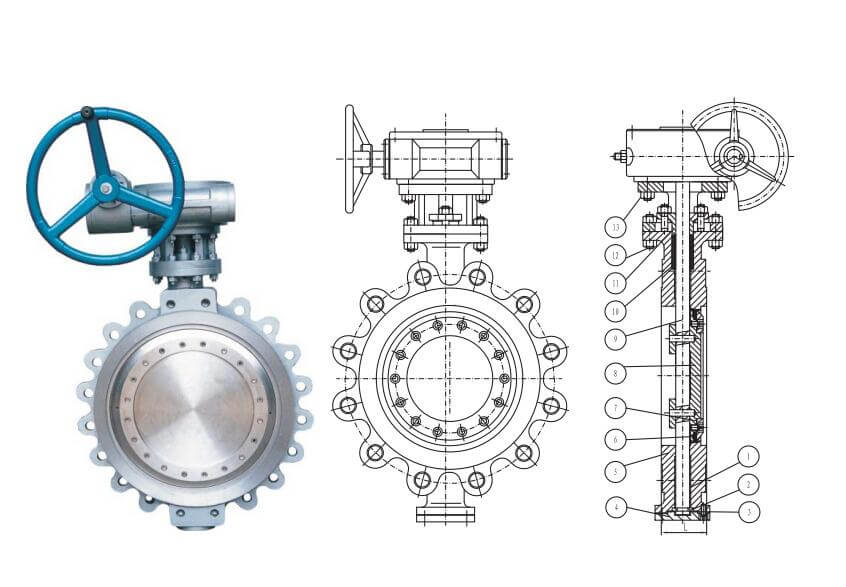

The butterfly plate rotary center of the triple eccentric metal sealed butterfly valve, that is, the valve shaft center, forms a dimension offset with the butterfly plate sealing surface, and forms an angular position with the valve body center line to form an angle between the offset valve body sealing surface center line and the valve seat center line (that is, the valve body center line).

Because the seat cente rline and the valve body center line form an angle offset on the basis of the double eccentric butterfly valve, the sealing surface of the butterfly plate immediately leaves the seat sealing surface in the opening process of the butterfly valve, and will contact and press the seat sealing surface only at the moment of closing.

When fully opened, a gap between the two seal faces is the same as that of the double eccentric seal butterfly valve. The design of this kind of butterfly valve completely eliminates the mechanical wear and abrasion between the two seal faces, and greatly improves the sealing performance and service life of the butterfly valve.

A relatively advanced butterfly valve is a triple eccentric metal hard-sealed butterfly valve, the valve body and seat are connected components, and the sealing surface layer of the seat is made of surfacing temperature-resistant and corrosion-resistant alloy materials.

The multi-layer soft stacked sealing ring is fixed on the valve plate. Compared with the traditional butterfly valve, this kind of butterfly valve has the advantages of high temperature resistance, easy operation and no friction. When closing, with the increase of the torque of the transmission mechanism to compensate the seal to improve the sealing performance and prolong the service life of the butterfly valve.

Leave A Comment